Job coating – perfection from A to Z

From optical, decorative and technical PVD coatings to sophisticated paint processes: Wohlrab caters to many industries. Our technologies are to be found e.g. as reflective technical layers, in EMC and ESD protection and in medical applications. A particular strength is in surface treatments for hearing aids, where we supply many renowned manufacturers.

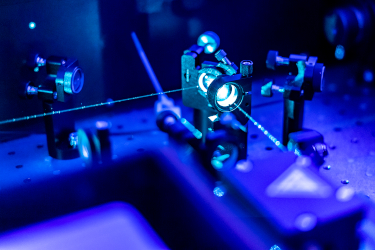

Excellent transmission, minimal reflection and absorption: with state-of-the-art plant technology, perfectly coordinated processes, and controlled manufacturing conditions, we develop and implement high-performance layer designs for plastics and technical glass – precisely according to your requirements. From process development to rigorous quality testing and flexible manufacturing, we accompany you with technical precision and tailored service.

Process engineering

The methods used are Electron Beam Evaporation, Ion-Assisted Deposition, and Magnetron Sputtering. Each of our processes is precisely tailored to meet the requirements of your optics.

- IAD system W 1100 pro from in-house production

- EBE system BAV 1250 and BAV 1050

- MS-/IAD system EVATEC MSP 1232

Manufacturing environment

Controlled manufacturing conditions and premium cleaning systems create the optimum basis for durable, high-performance and reliable precision optics.

- UCM-PerformanceLine ultrasonic cleaning system

- Fully air-conditioned cleanroom with H13-filtered supply air and slight overpressure; partially laminar flow H14-filtered

- Oil-free vacuum pump system

Recipes

Proven layer designs and premium development expertise for your high-performance coatings – flexibly implemented according to your specifications.

- Comprehensive portfolio of standard HR and AR coatings in the VIS and NIR range

- Specifically customized and developed coatings according to customer requirements for beam splitters, filters, AR and HR

- Metallic mirrors made of Ag, Al and Au (unprotected, protected or enhanced)

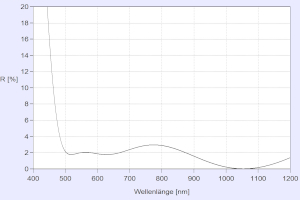

Performance parameters

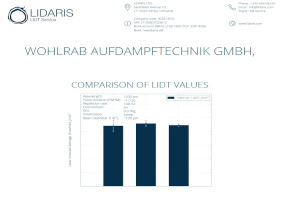

LIDARIS and IOF independently validated the precision of our fine optical coatings. Absorption and LIDT measurements can be conducted at any time at LIDARIS, IOF, or LZH.

- Laser-induced damage threshold (LIDT)

- up to 15,07 J/cm² at 1030-1064 nm

- up to 6,8 J/cm² at 515-532 nm

- Transmission > 99,95 % at 1064 nm

- Low absorption < 2,3 ppm

Service

Whether you need standard coatings or customized solutions, we will support you professionally and flexibly to achieve your desired result. Your requirements will be individually qualified and proactively implemented.

- Evaluation of your specifications according to proven coating recipes with smooth execution

- Coating engineering for highly specific solution needs, innovation process including sampling

- Lot sizes: from individual pieces and prototypes to series production

- Flexible production quantities, scalable capacities

- Delivery times: for standard parameters 2-3 weeks; shorter delivery times are available upon request

Wohlrab‘s most commonly supplied technical coatings are PVD* or PECVD* based and can be found e.g. in EMC and ESD protection, reflective layers or anti-glare coatings. Miscellaneous special coatings are also available for optics, sensors and medical technology.

*PVD = physical vapour deposition

*PECVD = plasma-enhanced chemical vapour deposition

EMC coatings (electromagnetic compatibility)

EMC protection is commonly provided to electronic components or subassemblies by adding a metal coating layer (1…5µm) to its housings. Depending on the application, we offer two different processes: thermal evaporation or sputtering.

Evaporation

Thermal evaporation is a thin-film deposition method, where a pure metal material is evaporated into vapour particles. These in turn condense back into a solid state when reaching the target substrate surface. Typical source materials are e.g. aluminium, copper or gold but depending on the application in question material combinations like Cu/NiCr, Cu/Sn can also be applied.

Combined PVD and paint process

Combined decorative coatings comprise thin metallic reflective PVD layers embedded in paint. The applied paint system has to be specifically selected for a given application. This is of particular importance for the final surface quality (colour, hardness, shininess and chemical resistance).

Automated robotic painting

Wohlrab‘s state-of-the-art robotic painting stations ensure a precise and reproducible high quality surface finish. To eliminate the impact of dust and contamination on the end result we operate with connected interlocked dust-free chambers. We also offer manual paint processes.

For more than ten years we have been developing innovative solutions for our customers in the medical industry, e.g. for hearing aids and other medical devices like OR lamps. Our long standing expertise in the development and production of these highly sophisticated coatings and a holistic understanding of the entire process chain allow us to meet even the strictest medical standards.

Our portfolio of biocompatible surface treatments covers technical coatings (masked EMC gold evaporation), decorative two-colour automated robotic painting, 6-colour pad printing, laser engraving and Easy-to-Clean nano coatings.

Highest sophistication

Biocompatible coatings have to fulfil complex and partly contradictory requirements. Thereby negative reactions on living organisms are not permissible, even in long term direct contact (e.g. hearing aid to skin). At the same time, a high resistance to sweat and cosmetics and - on top of that - also high abrasion resistance are mandatory.

Paints and shades

Thanks to our close cooperation with our paint suppliers there is almost no limit to the colours we can offer for biocompatible coatings - just contact us. Both top and protective coats meet the highest demands of the hearing aid industry. Our base coats are available in white as well as a wide range of colours. We offer top coats from matt to high gloss and soft touch.

Whether it is micrometre thin coatings on plastic parts and films, delicate gold plating or high-resistance coatings for the automotive industry - the comprehensive expertise of our engineers pooled with state-of-the-art equipment allows us to tailor our technical solution to your particular challenge, regardless of its complexity. This makes Wohlrab your number one go-to-partner.

Project example: Highly conductive titanium coating on ceramic substrates

Requirements: Highly conductive (< 4 Ohm/sq) and adherent titanium coating for power electronics

- Modification of a sputtering system developed by Wohlrab

- In-house coating-layer development according to customer specifications

- Halving the surface resistance and proximity to the theoretical optimum

- Benefit: targeted implementation through consolidated know-how (coating development and plant construction-engineering)

Project example: EMC shield on a hearing aid housing cover

- Masked, selective gold evaporation layer for the very highest requirements on EMC shielding and chemical resistance

- In-house design, development and masking

- Specially designed PVD process and equipment for minimum heat impact on the substrate

- Benefits: rapid development, short delivery times